Operational efficiency and effective maintenance practices are crucial for industries seeking to optimize their productivity, minimize downtime, and reduce costs. In this pursuit, vibration monitoring has emerged as a powerful tool that offers valuable insights into the health and performance of machinery and equipment. This article provides a comprehensive market overview of vibration monitoring, highlighting its role in enhancing operational efficiency and maintenance practices across various industries.

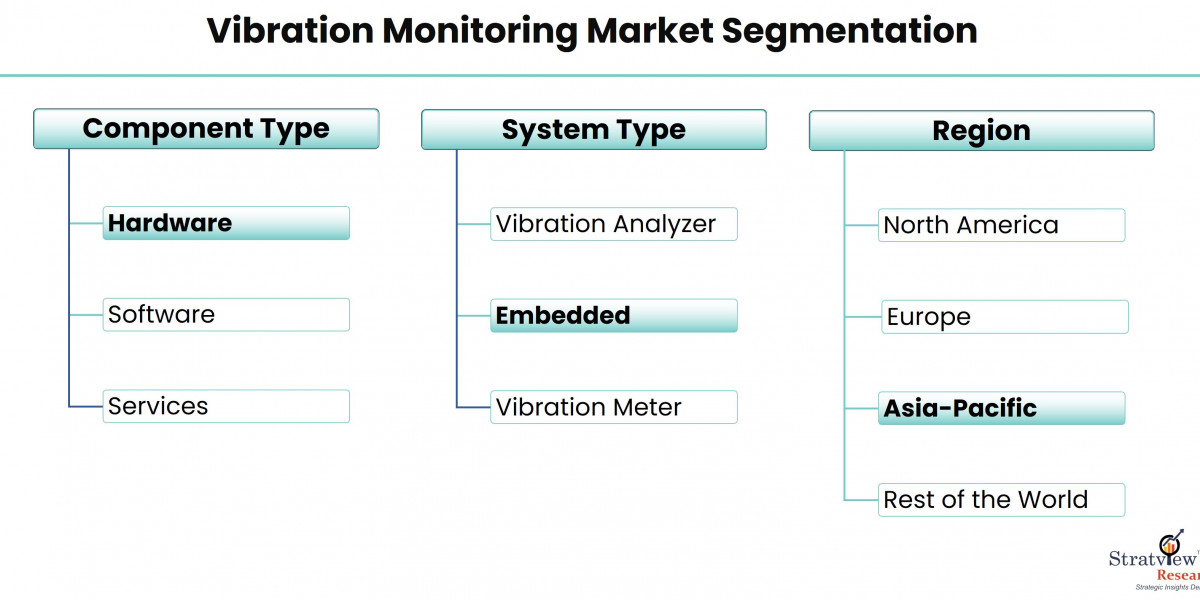

According to Stratview Research, the vibration monitoring marketwas estimated atUSD 1.45 billion in 2021and is likely to grow at aCAGR of 6.8% during 2022-2028to reachUSD 2.3 billion in 2028.

Understanding Vibration Monitoring

Vibration monitoring involves the measurement and analysis of vibrations generated by machines and equipment during their operation. By monitoring vibrations, industries can gain insights into the condition of their assets, detect potential faults or anomalies, and take proactive measures to prevent failures. Vibration data helps identify issues such as misalignment, imbalance, bearing wear, and other factors that can lead to equipment breakdowns.

The Importance of Operational Efficiency

Operational efficiency is a key driver of success for industries. It enables them to optimize production processes, reduce waste, and maximize output while minimizing resource consumption. Vibration monitoring plays a pivotal role in enhancing operational efficiency by providing real-time data on the health and performance of machinery.

By continuously monitoring vibrations, industries can identify inefficiencies and suboptimal operating conditions that may hinder performance. For example, excessive vibrations can indicate misalignment or imbalance, leading to energy wastage and reduced efficiency. Vibration monitoring allows for timely adjustments, ensuring machines operate within optimal parameters, thereby maximizing operational efficiency.

Advantages of Vibration Monitoring in Maintenance Practices

Effective maintenance practices are essential for industries to minimize unplanned downtime, extend the lifespan of assets, and reduce maintenance costs. Vibration monitoring offers several advantages in this regard:

Predictive Maintenance: Vibration monitoring enables the transition from reactive maintenance to proactive maintenance strategies. By continuously monitoring vibrations, industries can detect early signs of equipment degradation or impending failures. This allows for timely intervention, scheduling of maintenance activities, and replacement of faulty components before catastrophic failures occur. Predictive maintenance helps minimize downtime, optimize maintenance schedules, and reduce costs associated with unscheduled repairs.

Condition-based Maintenance: Vibration monitoring provides valuable data on the condition of machinery, helping industries adopt a condition-based maintenance approach. Rather than relying on fixed maintenance schedules, condition-based maintenance uses real-time data to determine when maintenance activities are necessary. By assessing the health of equipment through vibration analysis, industries can optimize maintenance resources, perform targeted repairs, and extend the operational life of assets.

Fault Diagnosis and Root Cause Analysis: Vibration monitoring facilitates fault diagnosis and root cause analysis. By analyzing vibration patterns and characteristics, maintenance personnel can pinpoint the underlying causes of abnormal vibrations. This information guides the maintenance team in troubleshooting and resolving issues effectively. Identifying root causes helps prevent recurring failures, leading to improved reliability and reduced maintenance costs.

Market Growth and Opportunities

The vibration monitoring market has experienced significant growth in recent years and is expected to continue expanding. The increasing adoption of predictive maintenance strategies, advancements in sensor technology, and integration with digital platforms such as the Industrial Internet of Things (IoT) have fueled the market's growth.

Opportunities in the vibration monitoring market are abundant, particularly in industries such as manufacturing, oil and gas, power generation, automotive, aerospace, and healthcare. These sectors rely heavily on the smooth operation of machinery and equipment, making vibration monitoring essential for maintaining operational efficiency and preventing costly failures.

Conclusion

Vibration monitoring is a critical tool for enhancing operational efficiency and maintenance practices in industries across various sectors. By continuously monitoring vibrations, industries can optimize their operational efficiency, detect faults, and take proactive measures to prevent failures. The adoption of vibration monitoring enables the shift from reactive to proactive maintenance strategies, leading to reduced downtime, extended asset lifespan, and improved reliability. As the market for vibration monitoring continues to grow,