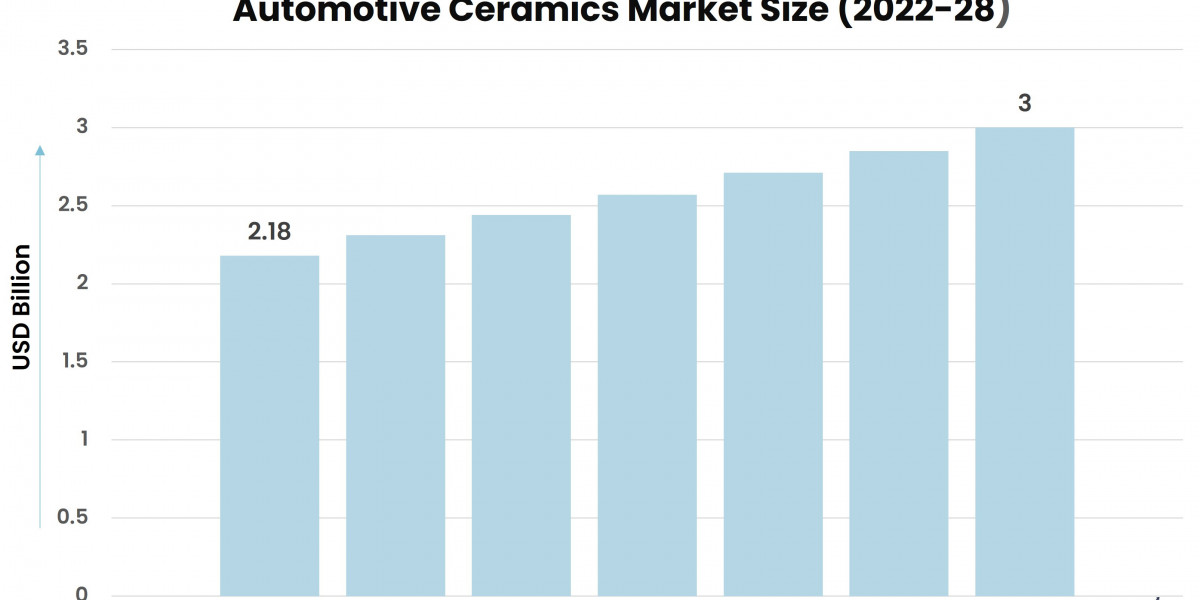

According to Stratview Research, the automotive ceramics market was estimated at USD 2.18 billion in 2022 and is likely to grow at a CAGR of 5.36% during 2023-2028 to reach USD 3 billion in 2028.

In the rapidly evolving landscape of automotive technology, the integration of advanced materials is steering the industry towards a future marked by efficiency, performance, and sustainability. Among these materials, ceramics have emerged as a driving force, revolutionizing various components in modern vehicles. This article takes a closer look at the trends shaping the automotive ceramics market, illuminating the innovative strides that are propelling the industry forward.

The Ceramic Revolution Under the Hood

As we peer under the hood of modern vehicles, a quiet but profound revolution is taking place – the integration of ceramics in critical automotive components. Traditionally associated with decorative and delicate items, ceramics are proving to be robust, heat-resistant, and wear-resistant materials, making them ideal for applications in the demanding environment of a vehicle's engine and drivetrain.

Ceramics in the Engine: Pushing Performance Boundaries

One of the notable trends in the automotive ceramics market is the increasing use of ceramics in the engine components. The high thermal stability and mechanical strength of ceramics make them ideal candidates for components such as spark plugs, pistons, and cylinder liners. These ceramic components contribute to improved combustion efficiency, reduced friction, and enhanced overall engine performance.

Turbocharged Efficiency: Ceramics in Turbochargers

Turbocharging has become a cornerstone of automotive efficiency and performance. In this realm, ceramics play a pivotal role in the design of turbocharger components. The lightweight nature and excellent thermal properties of ceramics contribute to the durability and efficiency of turbochargers, allowing for increased power output and fuel efficiency.

Lightweight Solutions: Ceramics in Brake Systems

Weight reduction is a key focus in the automotive industry for achieving fuel efficiency and better handling. Ceramic materials are increasingly finding their way into brake systems, particularly in the form of ceramic brake pads and discs. The lightweight nature of ceramics not only reduces unsprung weight but also enhances braking performance, providing a smoother and more responsive driving experience.

Powering Electrification: Ceramics in Batteries and Electronics

With the rise of electric vehicles (EVs), ceramics are becoming integral to the development of advanced batteries and electronics. Ceramic materials are employed in battery components, such as separators and electrodes, contributing to the efficiency and safety of electric propulsion systems. Additionally, ceramics are used in electronic control units (ECUs) and sensors, supporting the growing sophistication of vehicle electronics.

Enhanced Durability: Ceramics in Transmission Systems

Transmission systems are subjected to high stresses and temperatures, making durability a critical factor. Ceramics, with their exceptional hardness and resistance to wear, are increasingly being incorporated into transmission components. Ceramic bearings and gears contribute to longer service intervals, reduced friction, and enhanced durability in both traditional and electric drivetrains.

Aesthetic Elegance: Ceramics in Automotive Design

Beyond functionality, ceramics are making their mark in automotive design, adding an element of aesthetic elegance. Interior components, such as trim pieces and controls, benefit from the exquisite finishes and unique textures offered by ceramic materials. This trend reflects a growing appreciation for the fusion of functionality and design in the automotive industry.

Sustainability Drive: Ceramics in Emission Control

The automotive ceramics market is aligning with the industry's increasing focus on sustainability. Ceramics are employed in catalytic converters, aiding in emission control by facilitating efficient conversion of harmful gases. This trend supports the automotive sector's commitment to reducing environmental impact and meeting stringent emissions standards.

Challenges and Opportunities: Navigating the Ceramic Road

While the adoption of ceramics in the automotive industry brings numerous benefits, challenges persist. High production costs, complex manufacturing processes, and the need for precise engineering pose obstacles. However, these challenges also present opportunities for innovation, cost reduction, and increased market penetration as the automotive ceramics sector continues to mature.

Global Dynamics: Regional Influences in the Ceramic Landscape

Understanding the trends in the automotive ceramics market requires considering regional dynamics. Different regions exhibit varying levels of adoption and preferences for ceramic applications. For instance, the Asia-Pacific region, with its burgeoning automotive industry, is a key player in driving the demand for ceramic components, while other regions contribute their own nuances to the global ceramic landscape.

Investments and Research: Fueling Ceramic Advancements

As the automotive ceramics market advances, significant investments in research and development are propelling new innovations. Industry players, ranging from established automakers to startups and research institutions, are investing in exploring novel applications, improving manufacturing processes, and pushing the boundaries of ceramic technology in automotive engineering.

Conclusion: Navigating the Ceramic Road Ahead

In conclusion, the trends in the automotive ceramics market paint a vivid picture of a transformative journey. From the engine bay to the braking system, ceramics are navigating the road ahead, driving the future of automotive technology. The integration of ceramics is not merely a trend; it's a paradigm shift that promises enhanced performance, efficiency, and sustainability. As automotive engineers and designers continue to explore the potential of ceramics, the industry is on a trajectory towards a future where these advanced materials will play an increasingly pivotal role in shaping the vehicles of tomorrow.