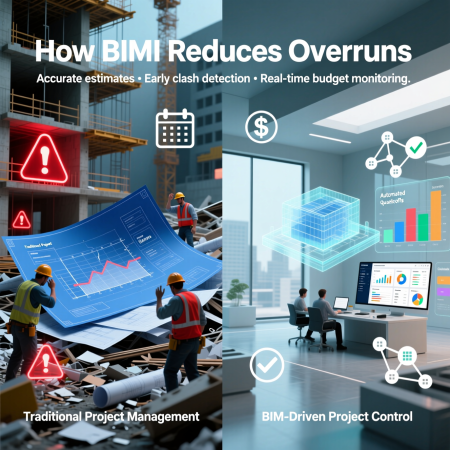

In the architecture, engineering, and construction (AEC) industry, we recognize that Building Information Modeling (BIM) revolutionizes project delivery by enhancing precision, collaboration, and foresight. BIM improves cost control through intelligent 3D modeling integrated with time (4D) and cost (5D) dimensions, enabling proactive management that minimizes financial risks. By addressing common causes of overruns—such as design errors, poor coordination, and inaccurate estimates—BIM improves cost control and significantly reduces project overruns.

- Understanding BIM: The Foundation of Effective Cost Management

- How BIM Enhances Cost Estimation Accuracy

- Clash Detection and Conflict Resolution: Preventing Rework Costs

- Improved Collaboration and Communication Among Stakeholders

- 4D BIM: Optimizing Scheduling to Avoid Time-Related Overruns

- 5D BIM: Dynamic Cost Control Throughout the Lifecycle

- Risk Management and Mitigation with BIM

- Material Management and Waste Reduction

- Case Studies: Real-World Evidence of BIM’s Impact

- BIM in Facility Management: Long-Term Cost Control

- Sector-Specific Applications

- Challenges in BIM Adoption and How We Overcome Them

- Future Trends: AI, IoT, and Digital Twins Enhancing BIM

- Implementing BIM: Best Practices for Maximum Benefits

- Suggestions / Recommendations

- FAQs

We leverage BIM to create a centralized digital representation of physical and functional characteristics, allowing all stakeholders to access real-time data. This approach not only streamlines workflows but also delivers measurable savings, with studies showing average cost reductions of 15-20% and time savings of up to 20% on BIM-enabled projects.

Understanding BIM: The Foundation of Effective Cost Management

Building Information Modeling (BIM) is a process involving the generation and management of digital representations of physical and functional characteristics of places. We use BIM to integrate multidisciplinary data into a single coherent model, facilitating better decision-making from conceptual design through operations.

At its core, BIM extends beyond traditional 3D modeling by incorporating:

- 4D BIM: Adding scheduling and sequencing.

- 5D BIM: Integrating cost data for dynamic budgeting.

- 6D BIM: Sustainability analysis.

- 7D BIM: Facility management post-construction.

These dimensions empower us to simulate scenarios, detect issues early, and optimize resources. BIM improves cost control by automating quantity take-offs (QTOs), reducing manual errors that often lead to overruns exceeding 20% in non-BIM projects.

We implement BIM using software like Revit, Navisworks, and CostX, ensuring interoperability through standards like IFC (Industry Foundation Classes). This interoperability prevents data silos, a frequent contributor to miscommunication and inflated costs.

How BIM Enhances Cost Estimation Accuracy

Accurate cost estimation forms the bedrock of project success. Traditional methods rely on 2D drawings and manual calculations, prone to omissions and inconsistencies. We adopt BIM for model-based estimating, where quantities extract directly from the digital model.

- Automated Quantity Take-Offs: BIM models contain parametric objects (e.g., walls, doors) with embedded data. We generate precise QTOs instantly, updating automatically with design changes.

- Real-Time Cost Linking: In 5D BIM, we attach cost databases to model elements. Changes in design reflect immediately in estimates, preventing lag that causes overruns.

- Scenario Analysis: We simulate alternatives (e.g., material substitutions) to identify cost-optimal solutions without physical prototypes.

Research indicates BIM-based estimating reduces errors by 30-50%, directly contributing to how BIM improves cost control and reduces project overruns. For instance, integrating BIM with tools like ConWize enables continuous updates, identifying discrepancies early.

We further enhance accuracy by incorporating historical data and AI-driven predictions, forecasting potential escalations from material price fluctuations or labor shortages.

Clash Detection and Conflict Resolution: Preventing Rework Costs

Rework accounts for up to 15% of project costs in traditional delivery. We utilize BIM’s clash detection features to identify conflicts between disciplines (e.g., MEP systems intersecting structural elements) before construction begins.

- Automated Clash Detection: Tools like Navisworks scan models for hard (physical) and soft (clearance) clashes, generating reports for resolution.

- Multi-Disciplinary Coordination: We host coordinated model reviews, where architects, engineers, and contractors collaborate in a common data environment (CDE).

- Reduced RFIs and Change Orders: Early resolution minimizes Requests for Information (RFIs), which delay projects and inflate costs.

Case studies demonstrate clash detection via BIM reduces rework by 40%, saving millions. For example, the Sutter Medical Center project achieved a 40% reduction in change orders, equating to $9 million savings.

By resolving 90% of clashes pre-construction, we ensure smoother execution, directly tying into how BIM improves cost control.

Improved Collaboration and Communication Among Stakeholders

Fragmented communication plagues traditional projects, leading to misunderstandings, delays, and significant cost overruns. We employ BIM’s collaborative platform to foster transparency and seamless interaction across all project phases.

In traditional workflows, information silos between architects, engineers, contractors, and owners often result in misaligned expectations, excessive RFIs, and costly disputes. We counteract this by establishing a Common Data Environment (CDE), where all stakeholders access a single source of truth.

- Common Data Environment (CDE): Platforms like Autodesk BIM 360 or Bentley ProjectWise serve as centralized repositories. All parties upload, view, and modify the latest federated model via cloud-based tools, ensuring version consistency and audit trails.

- Real-Time Updates and Version Control: Any design change—such as modifying a structural element—propagates instantly across the model. This eliminates outdated drawings, reducing errors from version mismatches that historically contribute to 10-15% of rework costs.

- Stakeholder Integration and Role-Based Access: Owners review progress dashboards, designers annotate models, contractors input constructability feedback, and subcontractors add shop drawings. We define clear Level of Detail (LOD) requirements and information exchange protocols in the BIM Execution Plan (BEP) to align contributions.

- Integrated Concurrent Engineering: Multi-disciplinary teams work simultaneously on the model, enabling value engineering sessions where alternatives are tested virtually.

This approach drastically reduces disputes and claims, primary drivers of overruns. Recent studies indicate BIM adoption yields 25-40% fewer RFIs and change orders. For instance, in healthcare projects, where coordination of MEP systems is critical, BIM-facilitated collaboration has reduced coordination issues by up to 50%.

We conduct regular virtual coordination meetings using BIM visualizations, such as 3D walkthroughs and AR/VR overlays, to ensure proactive alignment. Tools like Navisworks for clash reporting and issue tracking further enhance resolution speed.

Additional benefits include improved risk sharing in Integrated Project Delivery (IPD) contracts, where BIM data supports transparent performance metrics. Global adoption trends show that in regions with high BIM maturity, like the UK and Nordics, collaboration efficiencies contribute to 15-20% overall cost savings.

We also integrate mobile apps for on-site access, allowing field teams to query models, log issues, and update as-built data in real-time, closing the loop between design and construction.

4D BIM: Optimizing Scheduling to Avoid Time-Related Overruns

Time overruns cascade into cost overruns through extended overheads, financing charges, and penalties. We integrate 4D BIM to link the 3D model with project schedules, enabling dynamic sequencing and foresight.

Traditional scheduling relies on Gantt charts disconnected from geometry, leading to unrealistic plans and frequent delays. 4D BIM visualizes construction sequences temporally, revealing inefficiencies early.

- Construction Sequencing Simulation: We animate build processes in tools like Synchro Pro or Navisworks Timeliner, identifying bottlenecks such as crane conflicts or access restrictions.

- Resource Optimization and Lean Planning: Link model elements to labor, equipment, and materials. This supports just-in-time delivery, reducing idle resources and storage costs.

- Progress Tracking and Earned Value Analysis: Overlay as-built data from drones, laser scans, or IoT sensors against the 4D plan. Deviations trigger alerts for corrective actions.

- Risk and Delay Forecasting: Simulate impacts of weather, supply disruptions, or labor shortages, building robust contingencies.

Meta-analyses confirm 4D BIM shortens timelines by 15-25%, with some projects achieving 30% reductions. This acceleration lowers financing costs and enables earlier revenue for owners.

We employ advanced features like location-based scheduling for linear projects and integration with Primavera P6 for enterprise-level planning.

In infrastructure, 4D has mitigated delays in tunnel and bridge projects by visualizing complex phasing. Recent 2025 studies highlight 20% average time savings in BIM-mature markets.

5D BIM: Dynamic Cost Control Throughout the Lifecycle

5D BIM stands as the pinnacle of how BIM improves cost control. We embed cost data into the model for continuous, accurate financial oversight from inception to handover.

Manual estimating and static budgets fail to adapt to changes, fueling overruns. 5D integrates quantities, rates, and contingencies dynamically.

- Cash Flow Forecasting and Budget Tracking: Real-time extraction of quantities links to cost databases (e.g., RS Means), generating accurate forecasts and variance reports.

- Change Impact Analysis and Scenario Modeling: Assess modifications instantly—e.g., material swaps show precise delta costs, enabling informed decisions.

- Earned Value Management (EVM) Integration: Combine progress from 4D with costs for performance indices, highlighting under/over runs early.

- Contingency and Risk-Adjusted Budgeting: Probabilistic modeling allocates reserves based on quantified risks.

Projects leveraging 5D report 10-20% cost savings, with error reductions up to 50%. We use tools like CostX or Vico Office for seamless 5D workflows.

Step-by-step 5D implementation: Define cost breakdown structure (CBS), link model objects to cost items, validate QTOs, and automate reporting.

Comparisons show traditional methods yield 20-30% inaccuracies vs. BIM’s near-real-time precision.

Risk Management and Mitigation with BIM

Unforeseen risks amplify overruns. We harness BIM for comprehensive, data-driven risk assessment and mitigation.

- Risk Simulation and Monte Carlo Analysis: Integrate with tools like @Risk to model probabilistic outcomes on cost and schedule.

- Contingency Planning with Quantified Risks: Prioritize risks via heat maps derived from model data.

- Safety Integration and Hazard Visualization: Virtual identification of fall risks, confined spaces, or clashes reduces accident costs.

BIM cuts risk exposure by 25-35%, per recent reviews. In high-risk sectors like infrastructure, it has prevented multimillion-dollar claims.

Material Management and Waste Reduction

Over-ordering and waste inflate costs. We utilize BIM for precise quantification and lean supply chains.

- Just-in-Time Procurement and Logistics Planning: Accurate QTOs inform procurement schedules.

- Prefabrication and Modular Support: Detailed models enable off-site fabrication, minimizing on-site waste.

- Sustainability and Circular Economy Optimization: Track embodied carbon and recyclable materials.

Projects achieve 20-35% waste reduction, equating to substantial savings. Sustainability ties yield LEED credits and lower lifecycle costs.

Case Studies: Real-World Evidence of BIM’s Impact

We illustrate how BIM improves cost control and reduces project overruns through diverse successes.

- St. Louis Art Museum Expansion: Clash detection saved $10 million in rework.

- Sutter Medical Center (USA): 40% fewer change orders, $9 million saved; healthcare coordination exemplar.

- Beijing National Stadium: Precise modeling minimized material waste.

- Queen Silvia’s Children’s Hospital (Sweden): Extensive BIM tracked 450 systems, ensuring on-budget delivery in complex healthcare.

- Indonesian Hospital Project (Recent): 50% time, 52% cost reductions via 5D.

- Saudi Arabia Rail Projects (2024 Review): 5D BIM minimized overruns in infrastructure.

- Sri Lankan Design-Build (2024): BIM mitigated overruns in building projects.

These span sectors, showing 15-50% reductions. Healthcare cases highlight MEP coordination savings; infrastructure demonstrates scalability.

Additional: UK hospital projects post-2016 mandate report 20% average savings.

BIM in Facility Management: Long-Term Cost Control

We extend BIM to 7D/asset management for operational efficiency.

- Asset Tracking and COBie Handover: Embedded data enables CMMS integration.

- Energy Analysis and Predictive Maintenance: Simulate performance, reduce utilities by 15-25%.

- Lifecycle Costing and Renovation Planning: Accurate predictions lower long-term expenses.

Owners gain 10-30% operational savings, amplifying ROI.

Sector-Specific Applications

Healthcare: Complex MEP, infection control layouts; BIM reduces coordination errors by 50%.

Infrastructure: Bridges/tunnels use 4D/5D for phasing, yielding 20-30% savings.

Global adoption: Market valued $9B in 2025, growing 11-16% CAGR.

Challenges in BIM Adoption and How We Overcome Them

Investment hurdles exist. We mitigate via:

- Comprehensive Training: Certified programs for proficiency.

- Phased Rollout: Pilots build confidence.

- Interoperability Standards: IFC and openBIM ensure compatibility.

ROI realized in 1-3 projects, often 100-1600%.

Future Trends: AI, IoT, and Digital Twins Enhancing BIM

Emerging integrations amplify capabilities.

- AI Predictive Analytics: Forecast overruns, automate clashes.

- IoT Real-Time Feedback: Sensors update models for dynamic control.

- Digital Twins: Living replicas optimize operations, reducing emissions 50%.

Trends project 30-40% efficiency gains by 2030.

Implementing BIM: Best Practices for Maximum Benefits

- Early Involvement: Conceptual phase maximizes value.

- Robust BEP and IPD: Clear roles, aligned incentives.

- Tool Selection and Integration: Compatible ecosystems.

This ensures optimal returns.

Suggestions / Recommendations

To fully harness how BIM improves cost control and reduces project overruns, we provide comprehensive, actionable recommendations based on industry best practices, global standards, and proven outcomes.

- Adopt Level 3 BIM Maturity with Integrated Digital Twins for Comprehensive Lifecycle Benefits: Progress beyond Level 2 (collaborative BIM) to Level 3, which emphasizes open data sharing, cloud-based management, and full lifecycle integration. At this stage, we create persistent digital twins—real-time virtual replicas synchronized via IoT sensors. These twins enable predictive maintenance, energy optimization, and scenario testing post-construction. Benefits include 20-40% reductions in operational costs over 30 years, enhanced sustainability through carbon tracking, and seamless renovations. Organizations like the UK’s Centre for Digital Built Britain advocate Level 3 for national infrastructure, yielding 15-25% total savings. We recommend starting with ISO 19650 compliance, selecting platforms like Bentley iTwin or Autodesk Tandem, and piloting on mid-sized projects to demonstrate ROI within 18 months.

- Mandate Comprehensive Training Programs and Adopt Integrated Project Delivery (IPD) Contracts: Successful BIM deployment hinges on skilled teams and aligned incentives. We enforce mandatory, role-specific training—covering software proficiency (Revit, Navisworks), process understanding (BEP development), and collaboration skills—through certified providers like buildingSMART. Training investment pays back 5-10x via reduced errors. Pair this with IPD contracts, where risks and rewards are shared among owners, designers, and contractors. IPD fosters early collaboration, reduces adversarial claims by 50-70%, and amplifies BIM benefits. Studies from the American Institute of Architects show IPD with BIM delivers projects 10-20% under budget and 15% faster. We suggest including BIM proficiency clauses in employment and multi-party agreements with pain/gain sharing mechanisms.

- Prioritize 5D BIM and Automated Clash Detection for Immediate and Substantial ROI: For organizations new to advanced BIM, we focus initially on 5D cost integration and clash detection—these deliver the fastest returns. Implement automated quantity take-offs linked to cost databases and change impact analysis to achieve 10-20% estimation accuracy gains from day one. Clash detection in tools like Navisworks resolves 80-90% of conflicts pre-construction, cutting rework costs by 30-50%. Quick-win strategies include retrofitting existing models for 5D and running weekly clash reports. Case evidence shows these features alone recover implementation costs within 6-12 months on projects over $10 million. We advise allocating 60% of initial BIM budget here before expanding to 4D/6D.

- Integrate AI, Machine Learning, and IoT Technologies Progressively to Enhance Predictive Capabilities: Begin with basic AI for automated clash detection and risk scoring, then advance to machine learning for predictive analytics on cost escalations and schedule delays. Incorporate IoT sensors for real-time site data feedback into digital twins, enabling dynamic adjustments. Progressive rollout—starting with AI-enhanced QTOs, then IoT for progress tracking, and finally full predictive modeling—minimizes disruption. Emerging tools like ALICE (AI planning) or VergeSense (IoT occupancy) amplify BIM, forecasting overruns with 85-95% accuracy and reducing contingencies by 20%. We recommend phased integration over 2-3 years, aligned with hardware upgrades and data governance policies.

- Require BIM Mandates in All Tenders and Procurement Processes for Industry-Wide Standardization: To ensure consistency, we embed BIM requirements in every tender—specifying minimum LOD, data formats (IFC), CDE usage, and delivery standards per ISO 19650. This levels the playing field, encourages subcontractor upskilling, and prevents low-bid anomalies from non-BIM approaches. Governments in the UK, Singapore, and UAE have mandated BIM for public projects, resulting in 15-30% sector-wide savings. For private clients, we include BIM Execution Plans as contract appendices with compliance audits. This standardization reduces interoperability issues, accelerates adoption, and positions organizations as leaders in efficient delivery.

Additional recommendations include:

- Establishing internal BIM champions and governance committees for sustained adoption.

- Conducting regular post-project reviews to quantify savings and refine processes.

- Partnering with software vendors for customized workflows and updates.

- Monitoring KPIs like RFI reduction, change order volume, and contingency drawdown.

- Exploring government incentives or certifications for BIM excellence.

Implementing these strategies positions projects for optimal cost control and minimal overruns, delivering superior value across the AEC ecosystem.

FAQs

- What is BIM? Building Information Modeling is a digital process creating and managing building data throughout its lifecycle.

- How does BIM improve cost control? Through automated QTOs, real-time updates, and 5D integration for dynamic budgeting.

- Can BIM reduce project overruns? Yes, by 15-38% via early issue detection and better coordination.

- What is 5D BIM? 3D model plus time (4D) and cost data for comprehensive financial tracking.

- How does clash detection work in BIM? Software scans models for conflicts, allowing pre-construction resolution.

- What savings can we expect from BIM? Typically 10-20% in costs, with case studies showing millions saved.

- Is BIM suitable for small projects? Yes, scaled implementation yields proportional benefits.

- How does BIM support sustainability? By optimizing materials and energy analysis, reducing waste.

- What tools are essential for BIM cost control? Revit, Navisworks, CostX, and BIM 360.

- Does BIM require special contracts? IPD or BIM-enabled contracts enhance collaboration.

- How does BIM handle changes? Automatically updates models and estimates.

- What are common BIM challenges? Initial training and interoperability, overcome with planning.

- Can BIM integrate with existing software? Yes, via open standards like IFC.

- How does BIM affect project timelines? Reduces by 20% through better planning.

- Is BIM mandatory in construction? Increasingly in many regions for public projects.